Main Functions and Features

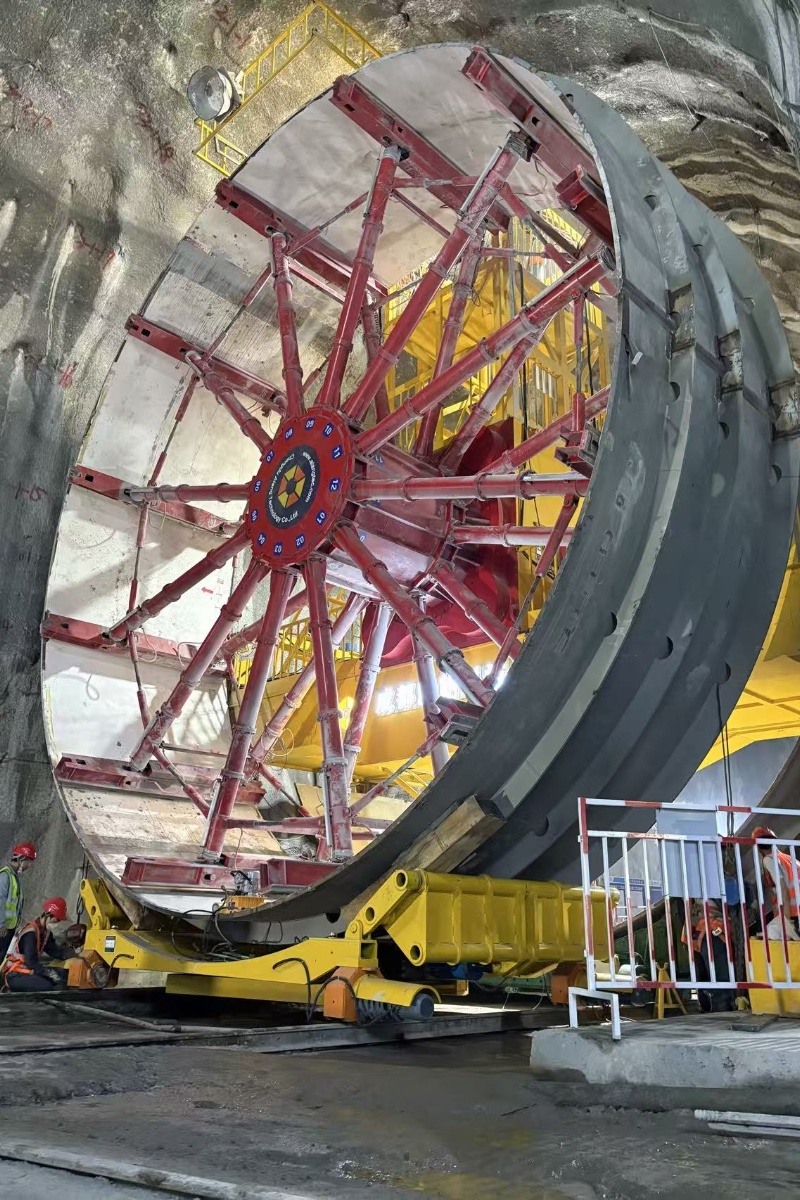

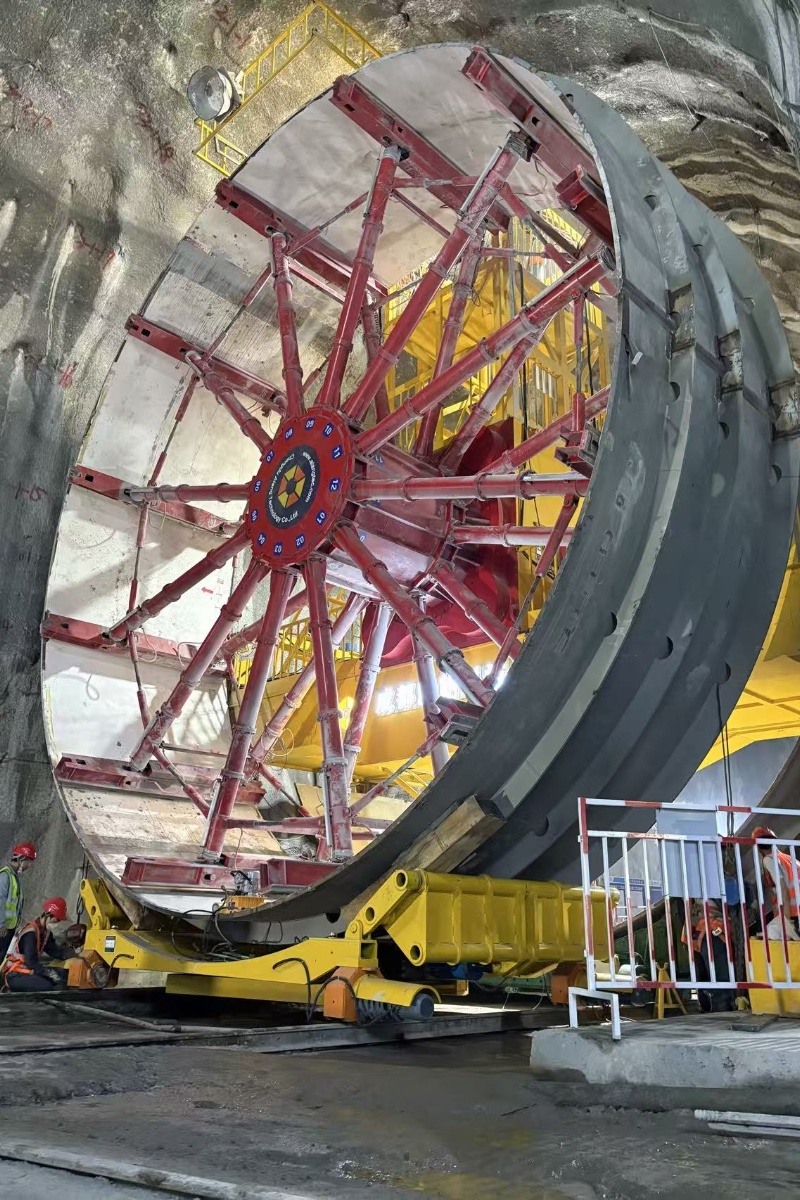

Fully Automated Process: This equipment automates the entire process from steel plate unloading, tile assembly, digital pipe rounding adjustment to welding, transforming the traditional manual circumferential pipe welding method.

High-Precision Assembly: The intelligent control system enables high-precision assembly of steel pipe tiles and pipe sections, ensuring weld alignment and gap accuracy, laying a solid foundation for subsequent welding.

Digital Rounding Adjustment: The equipment features digital pipe rounding adjustment, automatically adjusting the roundness of the steel pipe to meet stringent construction requirements.

Intelligent Welding:

Automatic Submerged Arc Welding: The equipment extensively utilizes automatic submerged arc welding technology, achieving efficient weld seam welding via a submerged arc welding carriage.

Real-Time Adaptability: Some advanced intelligent welding systems can adjust welding parameters in real time to adapt to changes in joint preparation and the site environment.

Multifunctionality: Some equipment integrates multiple welding processes, such as gas shielded welding (GMAW/FCAW) and submerged arc welding (SAW), to adapt to different welding requirements.

High Efficiency: Compared to traditional manual welding, intelligent welding machines significantly improve welding efficiency, shorten construction time, and in some cases, increase productivity several times over.

High Quality Standards: Through precise parameter control and automated processes, intelligent welding machines ensure high consistency and reliability of weld quality, reducing human error and rework rates.

Improved Working Conditions: Automated equipment reduces close contact between workers and harmful environments such as high temperatures and fumes, greatly improving working conditions and reducing labor intensity.

Modular Design: The equipment adopts a modular design, making it suitable for large-scale application in engineering projects.

Application Cases and Technical Specifications

Application Cases: In large-scale hydropower projects such as the Suwalong Hydropower Station in China, intelligent welding machines for pressure steel pipes have been successfully applied on a large scale, effectively improving the welding process level of the projects.

Technical Specifications: To standardize the construction technology of intelligent welding machines in hydropower projects, the "Technical Specification for Intelligent Welding Construction of Pressure Steel Pipes in Hydropower Projects" (NB/T 11562-2024) has been published and is being promoted. This procedure applies to the intelligent assembly welding of pressure steel pipes with a diameter of not less than 5 meters.

Components A typical intelligent assembly welding system usually includes:

Intelligent assembly welding machine: Responsible for core functions such as tile assembly, digital rounding, main machine steering, and lifting.

ulti-functional roller welding trolley: Used for transporting, supporting, and adjusting the steel pipes in all positions.

Intelligent submerged arc welding trolley: Responsible for automated submerged arc welding.

Control system: Integrates digital and intelligent control modules to achieve precise control of the entire assembly welding process.

WhatsApp

WhatsApp Phone

Phone