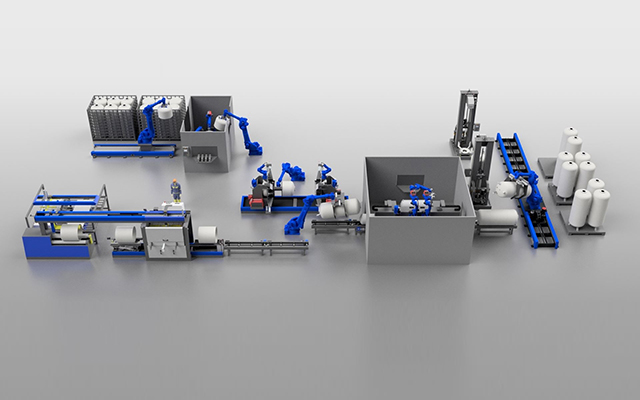

A Gas tank robot production line is a fully automated manufacturing system designed for the efficient, precise, and safe production of gas storage tanks, including LPG cylinders, industrial pressure vessels, and household gas containers. By integrating robotic welding, cutting, assembly, inspection, and coating technologies, this production line greatly enhances productivity, product consistency, and quality control.

The system typically consists of multiple intelligent workstations such as automatic loading and positioning units, robotic welding stations, leak testing systems, painting or powder-coating lines, and automated conveying systems. Through centralized digital control and real-time monitoring, each stage of production is seamlessly connected, forming a continuous and efficient workflow.

Key Advantages:

High production efficiency due to continuous robotic operation and reduced manual intervention.

Superior welding and assembly precision, ensuring leak-free and durable tanks.

Enhanced safety, minimizing operator exposure to hazardous environments.

Consistent quality control with integrated inspection and data feedback systems.

Scalability and flexibility, suitable for various tank sizes and specifications.

Applications:

This automated line is widely used in the energy, chemical, and manufacturing industries, particularly for producing LPG tanks, CNG cylinders, industrial air tanks, and fire extinguisher shells. It meets the growing market demand for high-quality, standardized, and mass-produced gas storage products.

In summary, the Gas Tank Robot Production Line represents a modern, intelligent solution for gas tank manufacturing. It integrates robotics, automation, and digital management to achieve high precision, efficiency, and safety, driving the evolution of smart factory production in the energy equipment sector.

WhatsApp

WhatsApp Phone

Phone

Comment

(0)